We have received payment for the content in this article. Learn more.

French motorcycle clothing specialist Furygan was formed in 1969 by Jacques Segura. As the name implies (“gant” being French for “gloves”), they started out making gloves for the cycle, ski and motorcycling sectors. Mr Segura soon became involved with racers, finding solutions for their specific needs and so expanding the range available to the public.

At the time, Furygan was also involved with the French military, supplying technical kit such as parachutists leather helmets and gloves for the infantry; a relationship they still maintain to this day.

50 years later, Furygan’s motorcycle range is expansive, encompassing a full range of leather and textile kit – including a range of denim jeans – specially designed for both men and women. They also offer racing suits for junior riders, leisurewear and backpacks. In 2019, they launched their Fury Airbag System.

Known across the world for their iconic leather garments and expertise, over 100,000 square metres of leather is used annually by the brand. Furygan uses high-quality skins from various origins, including Italy and South America. Each skin is checked by hand by the skilled staff at their HQ in Nimes, France, and then cut on high-tech cutting tables. Custom race suits are still cut by hand by craftsman – many who have been at the company for decades. The factory can cut up to 800 garments a week which are then shipped to Furygan’s assembly factory in Tunisia.

While a cow skin is usually 1cm thick, Furygan will only use the 1 – 1.4mm of the leather – the remainder is used by other industries such as furniture -and it takes around 2.5m2 to make one jacket.

The same grade of leather is used to make the kit you buy as is used in the manufacture of the race suits worn by their sponsored riders, such Tetsuta Nagashima in MotoGP, World Supersport rider Andrea Locatelli and UK rider Tom Booth-Amos, currently leading the World Supersport 300 Championship.

But it’s not just leather garments made by the brand – the textile range is just as impressive. A range of polyamide, cotton, and polyester fabrics are used, depending on where on the garment they are used. The fabrics are held together using thick, high-tenacity polyamide or polyester threads, with areas exposed to abrasion covering the stitching with a fold of fabric.

Kevlar and cotton blends are utilised for comfort and protection. Always innovating, they worked closely with Kevlar to develop the world’s first AAA CE-Approved hoody, the Furygan Brad X Kevlar®.

All jackets and trousers are equipped with D3O armour, a partnership born from wanting to equip riders with protective but comfortable kit.

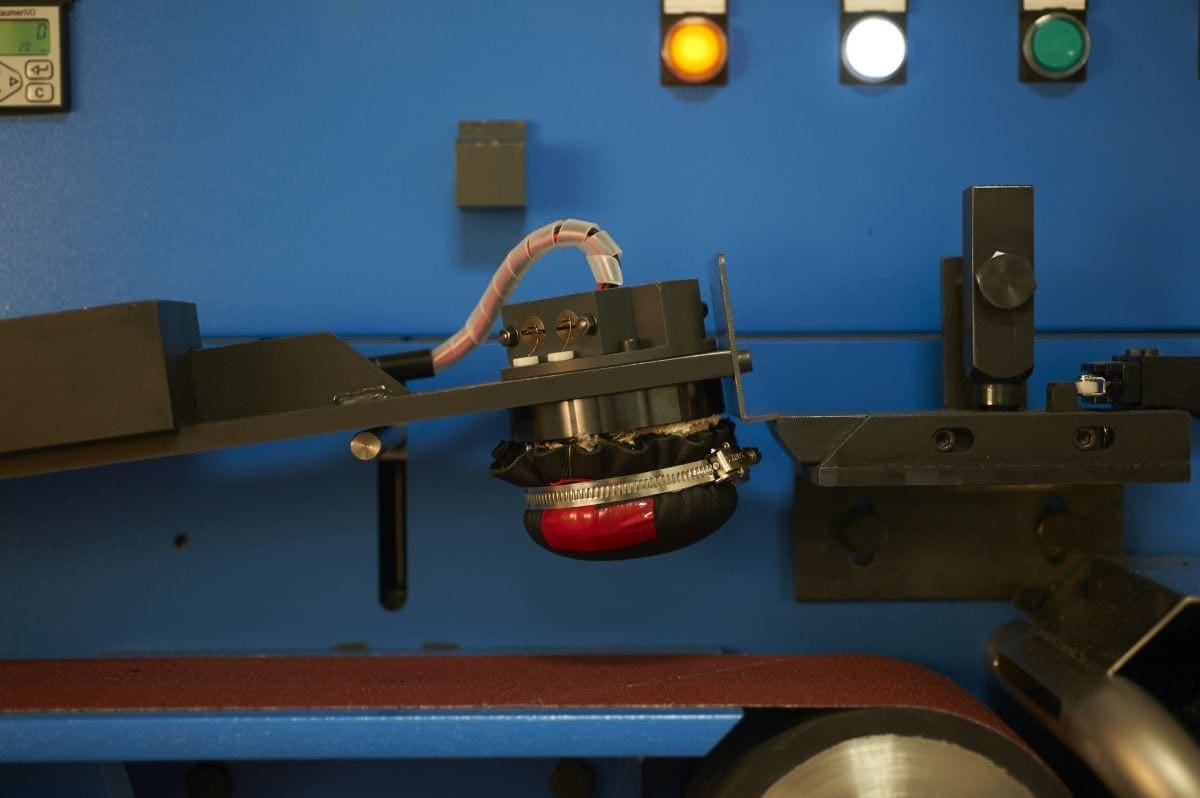

The entire Furygan range is CE-certified and has been developed in their state-of-the-art testing facility “Motion Lab”: This ensures any potential new item can be tested to CE certification level and improved as needed before applying to the official bodies for certification.

Motion Lab

Furygan’s obsession with quality is demonstrated by their state-of-the-art R&D facility, the Motion Lab. Here, they perform abrasion, impact, cut, tear and ergonomic tests, allowing them to develop products efficiently and independently.

Understanding that riding gear is a ‘second skin’, Furygan not only aim to make it safe, but also comfortable.

The abrasion tests exceed certification standards, replicating a slide on highly abrasive asphalt as well as simulating the impact and mechanical stress suffered by materials when they hit the ground. A number of tests check for resistance to cuts and tears (the ‘hidden enemy of the biker’), and ensure armour does not move out of position in an impact/slide situation.

Quite simply, Motion Lab allows Furygan to develop kit they know will pass the most stringent testing criteria.

What does it cost

Sticking with riding kit, prices range from £39.99 for the textile Jet D3O gloves to £709.99 for the Full Ride (airbag ready) one-piece leather suit.

Where are they

Furygan’s HQ is in Nimes, France, but it’s stocked in 43 countries across the world, including the UK.

Product review: Furygan Jet D30 gloves

It was somehow fitting that, given Furygan’s origins, we should test a pair of gloves for this feature.

A Summer glove carries it’s own specific demands. They should be thin enough to give great feel but still provide protection, they should allow airflow to the hands keeping them dry. The lining needs to stay in place; trying to put back on a pair of gloves with a wet, loose lining after filling up is a nightmare.

The Jet D30 is Furygan’s entry level Summer glove. Like all Furygan kit, it has been through thorough testing in their ‘Motion Lab’ prior to submission for PPE approval (The Jet D30 has a Performance Level 1 rating, meaning it passes the basic criteria for rider protection).

The upper is a mix of Nylon, Polyurethane and SBR (a synthetic rubber) with PVC knuckle protection and dots of D30 protecting finger joints. The palm is 100% goat leather, with reinforcement at impact areas. The gloves are fastened at the wrist via a single Velcro strap. They also feature Furygan’s ‘Sensitive Science Insert’ on the thumbs, allowing you to operate your mobile (or other touchscreen device).

This blend of materials makes the Jet D30 out of the box comfortable. Furygan’s gloves are a snug fit (their Large is a size 9, many other brands it’s a size 10, on a Summer glove this is ideal) and very light at just 65 grams.

They slip on easily, the Velcro wrist strap is simple to operate even in gloved hands. They are a short glove designed to work in conjunction with Furygan’s own jackets, but I have tried them with a number of other jackets (including my leather with narrow cuffs) and they were fine each time, as the narrow wrist and flat strap slip nicely within the sleeve.

They give a nice level of feel on the bike without feeling ‘flimsy’. The airflow to the fingers is good (on the move my fingers stayed cool and I was riding in temperatures in the 30s). I have been able to get them on and off without any problems. The thumb/forefinger span is generous, making it easy to operate controls. I was also able to work all zips, press studs etc. with them on, useful when you want to get to your mobile/SatNav, which you can operate in gloves thanks to the thumb insert.

How to get in touch

For more information, or to find your local authorised Furygan dealer, visit: www.nevis.uk.com or call 01425 478936.